When highly abrasive bulk materials thick-walled steel or cast-iron pipes, It is worn-out in a short span of time. This results in unscheduled shutdowns, production loss with higher cost of repair maintenance and labour cost. This indirectly impact in less productivity of plants.

Due to unplanned shut down, the money saved by using low cost steel piping components can result in much higher cost. Ceramic Lined pipes and fittings save money as repair frequency is greatly reduced and production time is increased.

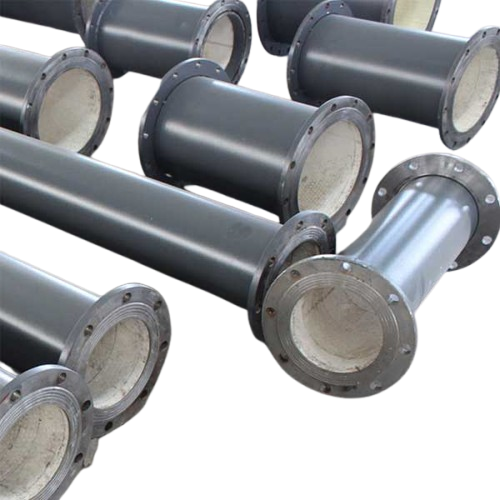

To reduce the severe abrasion of the bends in pneumatic systems, abrasion resistant piping components with internal linings – such as High Alumina Ceramic liners – should be used.

Coal is one of the main sources of fuel used in power generation. Coal fired boilers adopt the method of pulverizing raw coal in pulverize or mills, conveying the pulverized coal-air mixture from the pulverize to the boiler burner for producing and utilizing steam to generate power. Fine coal particles at higher velocities cause failure in many components in the pulverize and the coal piping system of the boiler. Ceramic lining is provided inside the component to extend the life thereby reducing downtime.