Global Techno Steel offers the broadest range of high Alumina Ceramic products which have extensively used in core industries like Power generation companies, Cement Manufacturing industries, Steel Industries etc.

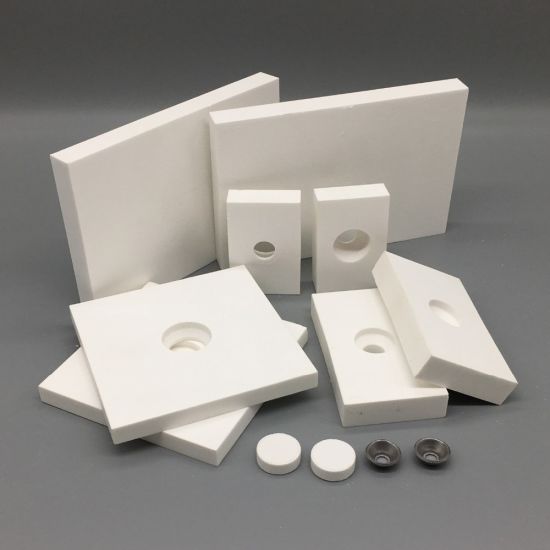

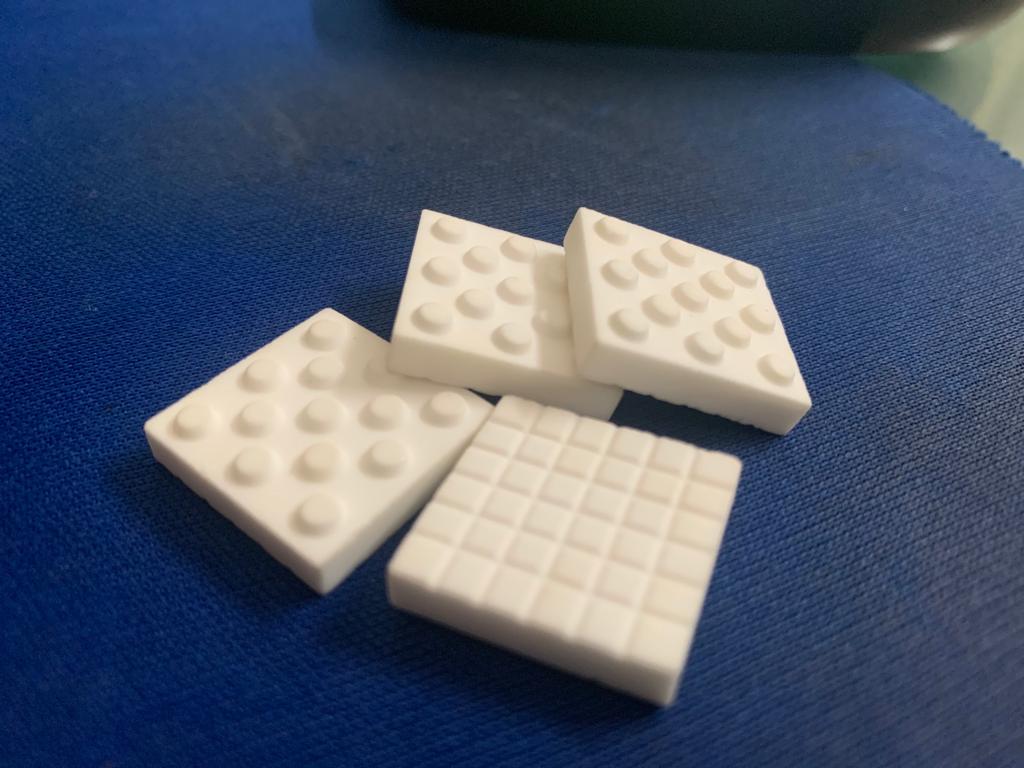

Tiles are formed by pressing a premix ceramic powder. Machining of product done before kiln firing for geometrically difficult shapes as per requirement of customer.

The thickness of the Ceramic lining depends on the severity of the abrasion and pipe diameter. Pipes smaller than 200 mm diameter will be protected with High Alumina Ceramic cylinders up to 25 mm thick. Pipes larger than 200 mm diameter normally are lined with tapered tiles from 6 mm to 25 mm thickness. Ceramic Cylinders of ID 40 mm to 200 mm of thickness 10, 15 & 20 mm